EasyWrap Window

With EasyWrap you benefit, among others, from its impressively compact design.

It is also suitable for working at a moderate pace or with an easily manageable amount of different profile geometries.

When it comes to efficiency and quality, EasyWrap offers you the same performance as all other machine types.

Ideal for

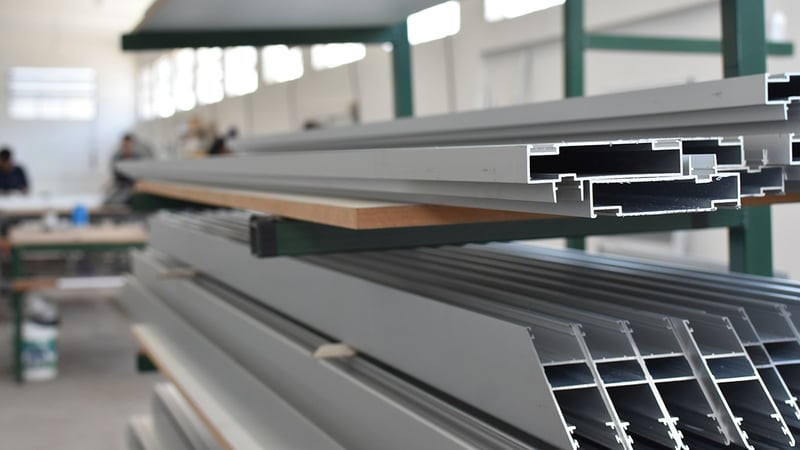

- Window profiles

- Window sills

- Other PVC profiles

- Profiles made from metal

Would you like to receive a free consultation to find out if EasyWrap Window is the solution you need?

Contact us for a non-binding, first conversation.

Description

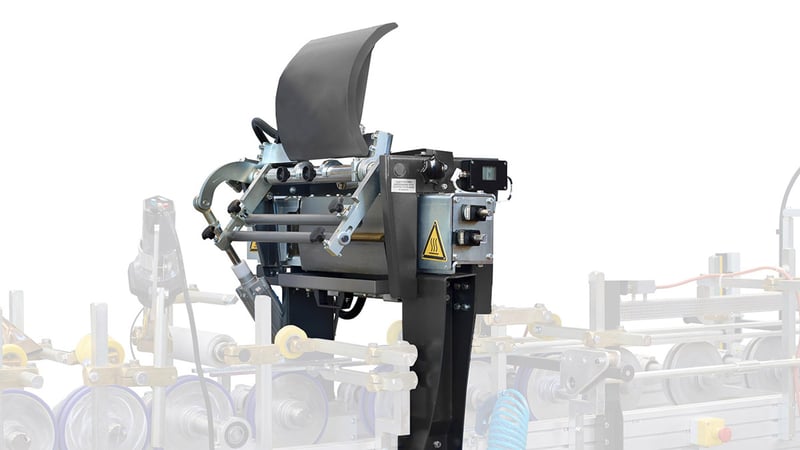

Its distinctive feature is the SCS unit, consisting of integrated systems such as its intelligent premelting device, the totally speed-stabilised adhesive dosing pump with quantity control, and our world-wide patented, infinitely adjustable slot nozzle.

The integrated premelter has been designed to melt adhesive on demand and prevent burnings.

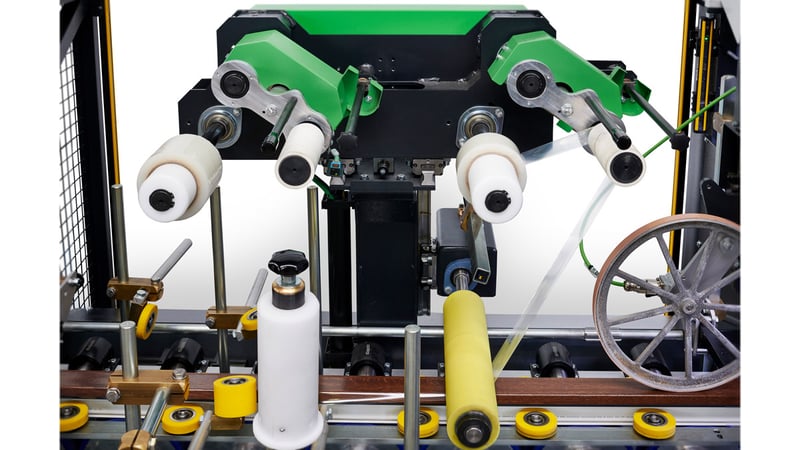

The set-up time reducing standard equipment of this type of machine includes lateral guides with parallel adjustment in the infeed, pressure rollers with tool-free quick-change system, quick-change cassettes in the wrapping area, and also the transport wheel with tool-free fixing.

The standard equipment on this series of machines includes:

-

SCS unit including premelter, adhesive dosing pump and slot coater

-

premelter for granular EVA, polyolefin and PUR in 2 kg or 18/20 kg pack sizes

-

Unwinding system with diameter dependent tension

-

Set-up aid for fast change of décor

-

Lateral guides with parallel adjustments

-

Quick-fix system for wrapping rollers

-

Tool-less adjustment of transport wheels for faster set-up

The optional equipment on this series of machines includes:

-

Vacuum application system PrimeStar or dosing system when working with felt strips

-

Double unwinding system or automatic reel changer for production without interruption

-

Web edge control for optimal position of surface material

-

Foil heating system for lower consumption of glue and better glue distribution

-

Central width adjustment in wrapping zone

-

Quick change cassettes for wrapping zone

-

Separating system SynCut 150G for automated separation

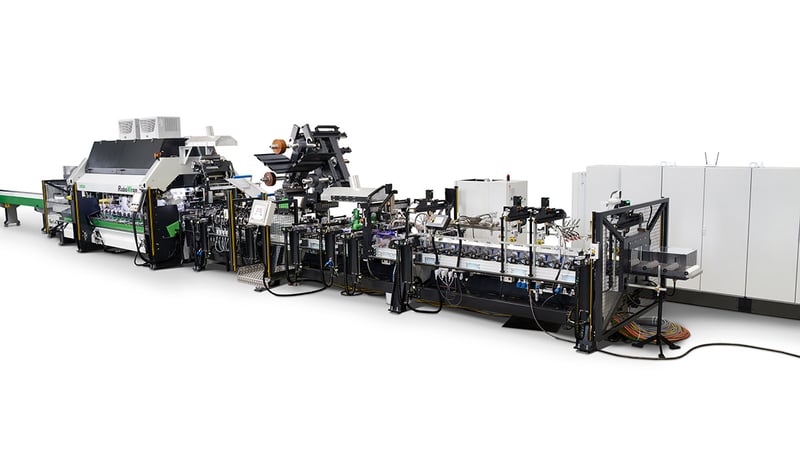

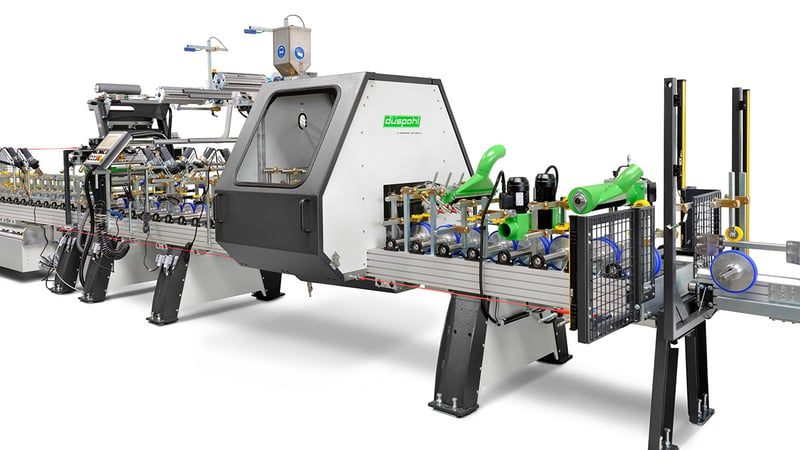

Possible configuration

Easy Wrap Window with DigiApp, Foil Heating System and Single Unwinding Station.

Control cabinet under the wrapping zone.

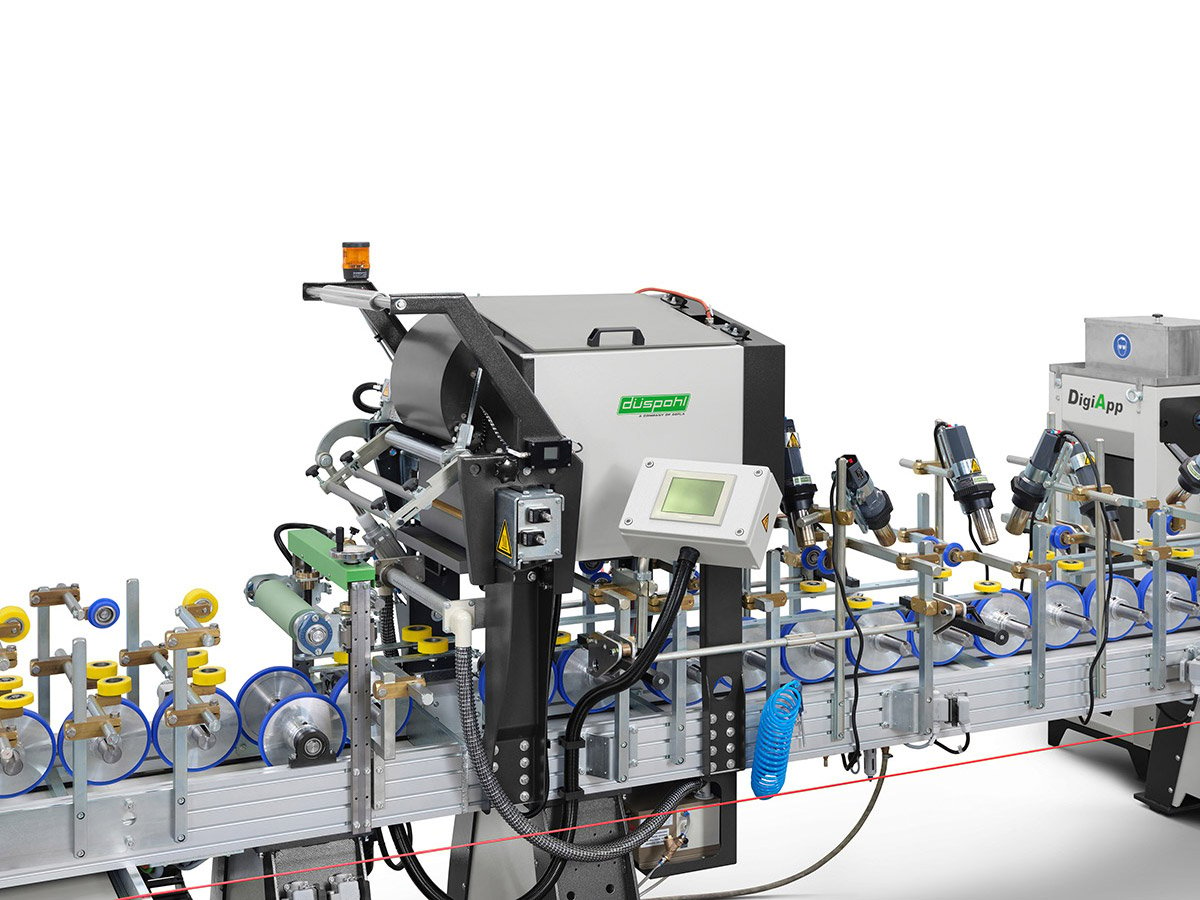

Essential element

SCS unit including premelter for EVA, PUR, PO, Slot Coater and dosing pump

special add-on: foil heating system

Highlights

-

Low energy consumption due to extremely compact design

-

Intelligent adhesive-preserving melting process

-

No need for extra space next to the machine for premelter

-

No need for heated hose connection

-

Modular construction allows for customised extension with the many additional units available

-

Reduced set-up time due to tool-free adjustment of transport wheel

-

Reduced set-up time due to tool-free replacement of wrapping rollers

-

Includes internationally renowned high quality Duespohl SlotCoater

Downloads

Pascal Flesch - Franz Jäger GmbH

We work with the machine (EasyWrap Window) every day and are very happy with its performance and functionality. Operating the line is easy and uncomplicated, which helps us save time and optimise the working process. Also, the quality of the wrapped products is impeccable and corresponds to our high standards.

A further advantage is the higher production flexibility. We can easily adapt the machine to the needs and requirements of our customers to fulfill individual wishes. At the same time, foiling our own window profiles gives us more control of the entire production process. This results in higher quality and minimises wastage.

We would like to especially point out Duespohl's customers service. Whenever there is a question or problems, the employees are always available, friendly and competent.