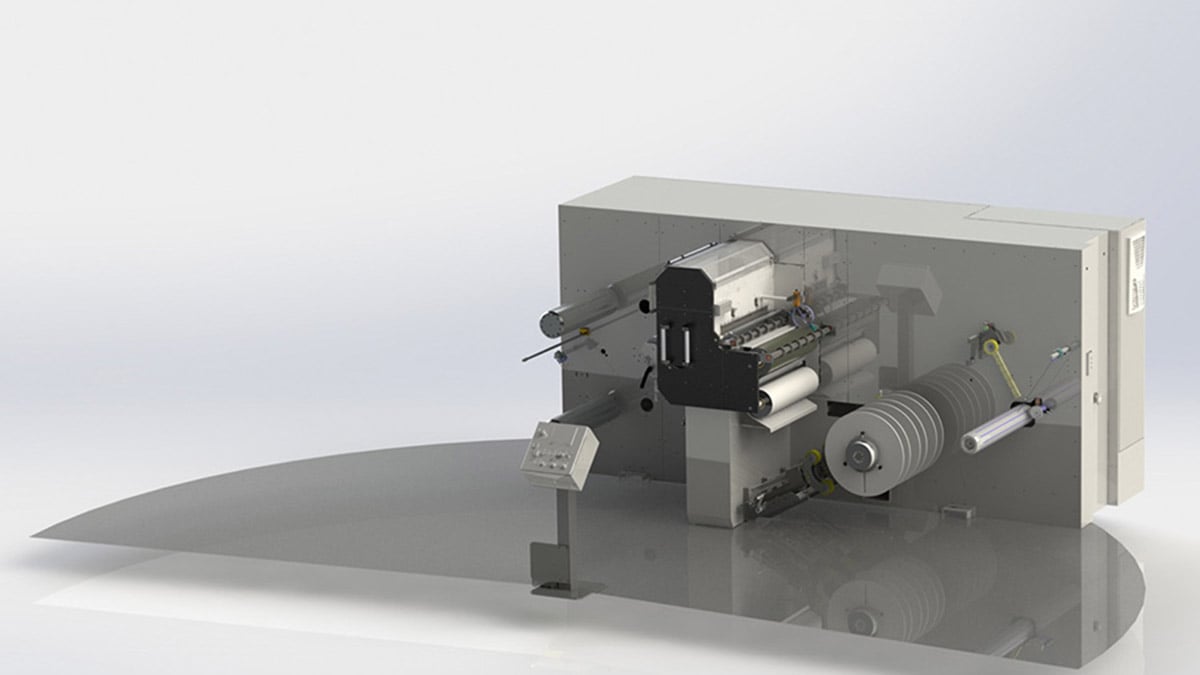

EdgeCut

EdgeCut processes edge material made from ABS, PVC, PP, paper, thermoplastic foils, laminates or fleece backed veneer up to a thickness of 2 mm.

This system does not only minimise the potential hazard to the operator, but also shortens setup times dramatically.

Ideal for

- Edge material

Would you like to receive a free consultation to find out if EdgeCut is the solution you need?

Contact us for a non-binding, first conversation.

Description

The cutting system developed by Duespohl makes it possible to cut and wind absolutely free of burrs and crease-whitening. The result is the highest quality in cutting thin papers, thermoplastic films and up to 2 mm thick edge materials, such as ABS or PVC. One of the biggest challenges was the fully automatic knife positioning as Duespohl’s well-known AutoCut performs it. The user specifies the desired cutting widths individually via touchscreen or retrieves them from a database. The adjustment process is completed in less than two minutes and guarantees a cutting width tolerance of no more than +/- 0.1 mm.

Technical data

- Material thickness: up to 2 mm, depending on material qualities

- Working width up to 700 m

- Strip width min.: 18 mm

- Roll diameter max.: 700 mm

- Cutting speed: 10-150 m/min

The optional equipment includes:

-

Automatic knife positioning

-

Auxiliary to position cardboard cores easily and speed up set-up times

-

Rewinding with friction winding shaft for equal rewinding results of all reels

-

Deionisation system

Highlights

-

Reels will be rewound with edges aligned

-

High drive power for ultra-tight winding results

-

Constant tension during unwinding and rewinding for constant rewinding results

-

Sensitive rewinding for sandwich foils with acrylic layers

Downloads