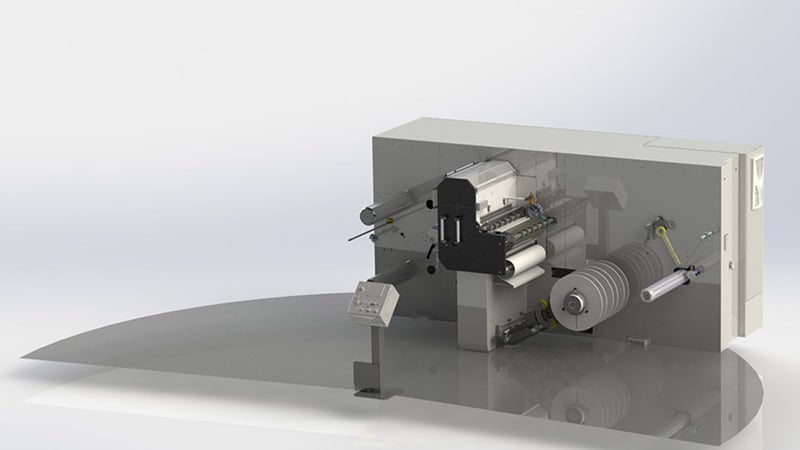

MasterSlice

Ideal for

- Surface material

Would you like to receive a free consultation to find out if MasterSlice is the solution you need?

Contact us for a non-binding, first conversation.

Description

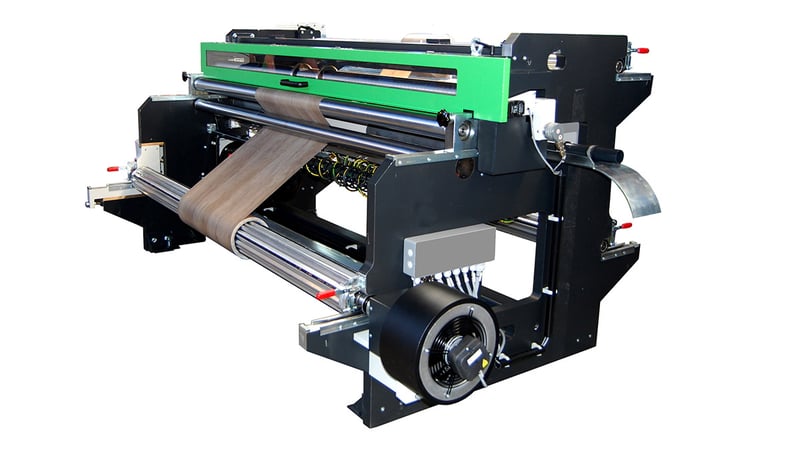

MasterSlice separates decorative material including the cardboard core using a saw. The reels carrying the material will be fixed in a way that keeps them from drifting away. This way, you will achieve a precisely positioned cut. Unlike similar solutions, MasterSlice performs a straight, linear cut.

The movable lifting table simplifies the handling and reduces the set-up time. The distance to the cutting tool contributes to the working safety. The programming of the working widths is intuitive and largely language-independent.

The optional equipment on this series of machines includes:

-

Moveable lifting table for faster and safer handling

Highlights

-

Highest possible cut quality and servo-driven feed rate control

-

Precise cutting position

-

Fast and safe handling

-

Very simple programming of the required division widths

-

Low maintenance, high availability

Downloads