PrimeStar ECOplus

Ideal for

- Window profiles

- Window sills

- Other PVC profiles

- Profiles made from metal

Would you like to receive a free consultation to find out if PrimeStar is the solution you need?

Contact us for a non-binding, first conversation.

Description

With this innovative primer application system PrimeStar ECOplus, the primer is directly applied by a coating head adapted to the profile geometry.

Regardless of the profile geometry, the layer thickness of the primer is the same on all parts of the profile’s surface. This in turn has a considerable influence on the efficiency of the subsequent drying process, and thus also allows higher feed rates.

The system works completely independent of positioning. Regarding the complexity of the profile geometries, there are no restrictions. For the simultaneous two-sided primer application, a Twin PrimeStar is available.

The achieved peel values are process-reliable, permanently repeatable and correspond to the current RAL-GZ 716.

The set-up time is reduced to a stunning 20 seconds.

More than 80 installations for international customers show that this efficient primer application system has become established in the plastic wrapping industry.

The standard equipment includes:

-

Application heads adapted to the profiles’geometries

The optional equipment includes:

-

TwinPrimeStar for application on both sides

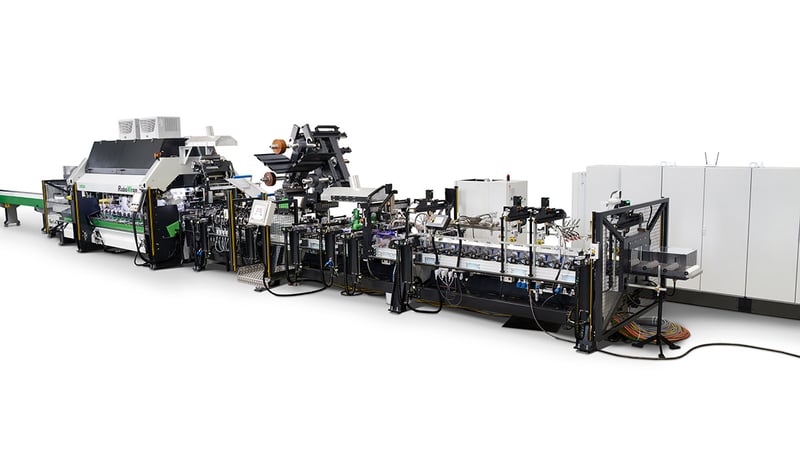

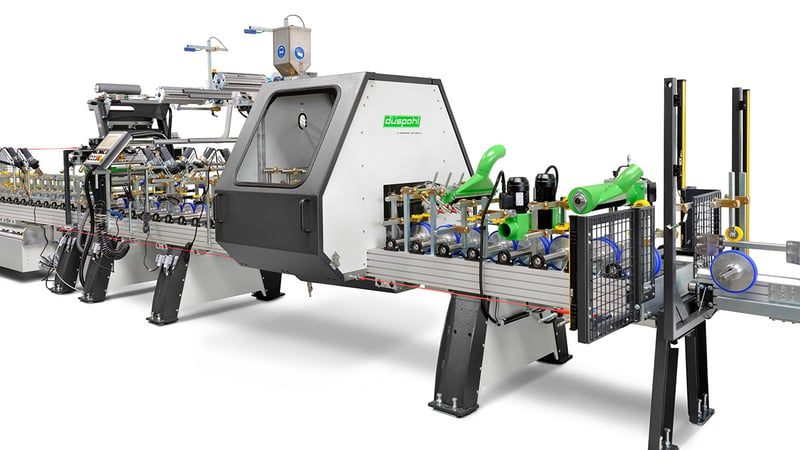

PrimeStar on machine

PrimeStar and its support require little space on your line

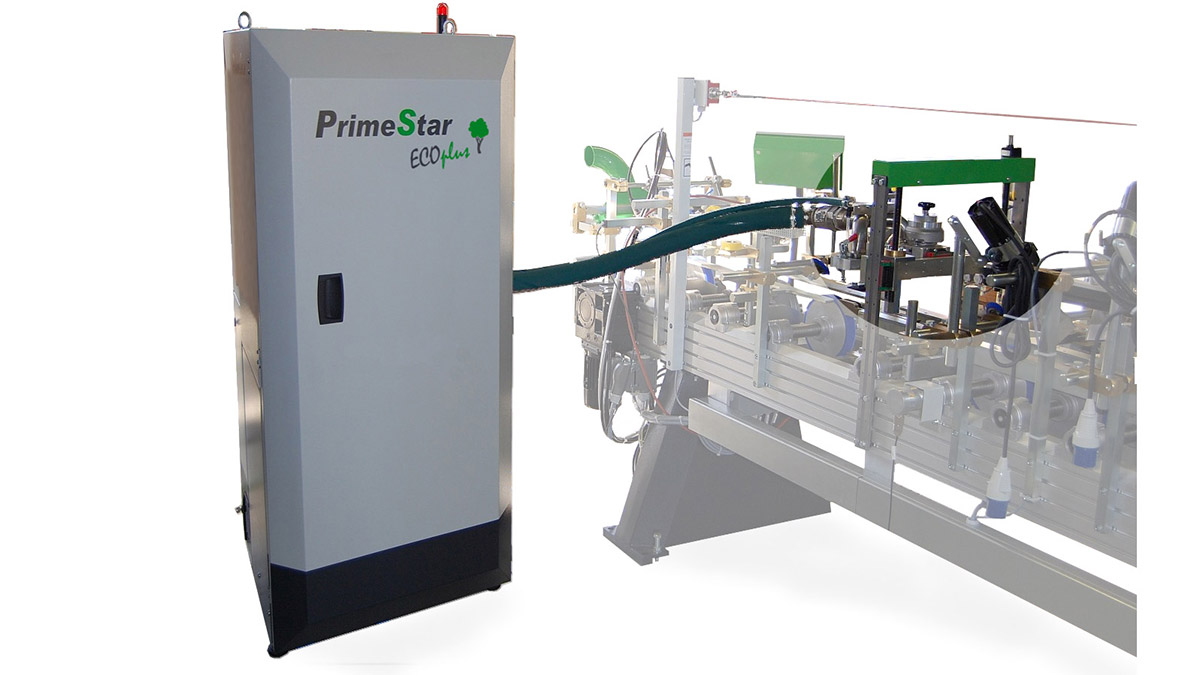

PrimeStar component

Vacuum application system

Connected to machine

Highlights

-

Absolutely homogeneous primer application, regardless of the profile geometry (see graphics in the gallery)

-

Primer heads constantly reusable - no continuous material costs for felt strips

-

Set-up time when changing profiles is reduced to a revolutionary 20 seconds

-

Layer-independent, streak-free primer application

-

The feed rate does not affect the primer application quality

-

Clean processing, as no dripping primer

-

Extremely small space required (400mm) within the primer application zone

-

Also available as retrofit for existing machines

Downloads