About us

Duespohl develops and manufactures profile wrapping lines, laminating lines including all components and related machines like slitting machines and parquet presses.

We supply customers from all over the world, mostly from the woodworking and plastics processing industries as well as third party contractors specialised in profile wrapping or foiling.

The common goal of our 60 Duespohl colleagues is to make technological progress useful for our customers. As a result, they realise an efficient and reliable production process as well as high quality and a long life of the final products

In our sector, we are known as the engine of innovation that develops new technologies and brings them – in cooperation with our partners of which some are scientific institutes – to market maturity.

Our research and development activities aim at the reduction of set-up times as well as on-going expenses, the reliability of the process by increasing reproducibility and the most efficient use of all resources ranging from the material to the energy input.

Our memberships

History of Duespohl

1960

As early as the 1960s, name giver Reinhard Duespohl founded the company, which years later was to be synonymous with innovation in profile wrapping. His ideas and the resulting revolutionary production methods were the trigger for the steadily growing company success.

2002

In 2002, Duespohl re-started with 6 employees.

Today, more than 60 highly motivated colleagues working in engineering, assembly, sales, purchase, logistics and administration fulfil the task of making the technological progress usable to our customers in the wood and PVC processing industries.

2005

Since 2005, the company has been part of the global Cefla group headquartered in Imola, Italy.

2021

Germany. 2021 was Duespohl’s best business year since the foundation of the company in 1967.

Profile wrapping and laminating lines made in Germany

Duespohl’s sole production site is in Schloss Holte-Stukenbrock, in the midst of a region in Germany that is well-known for its furniture and machine engineering industries with a strong focus on advanced technologies.

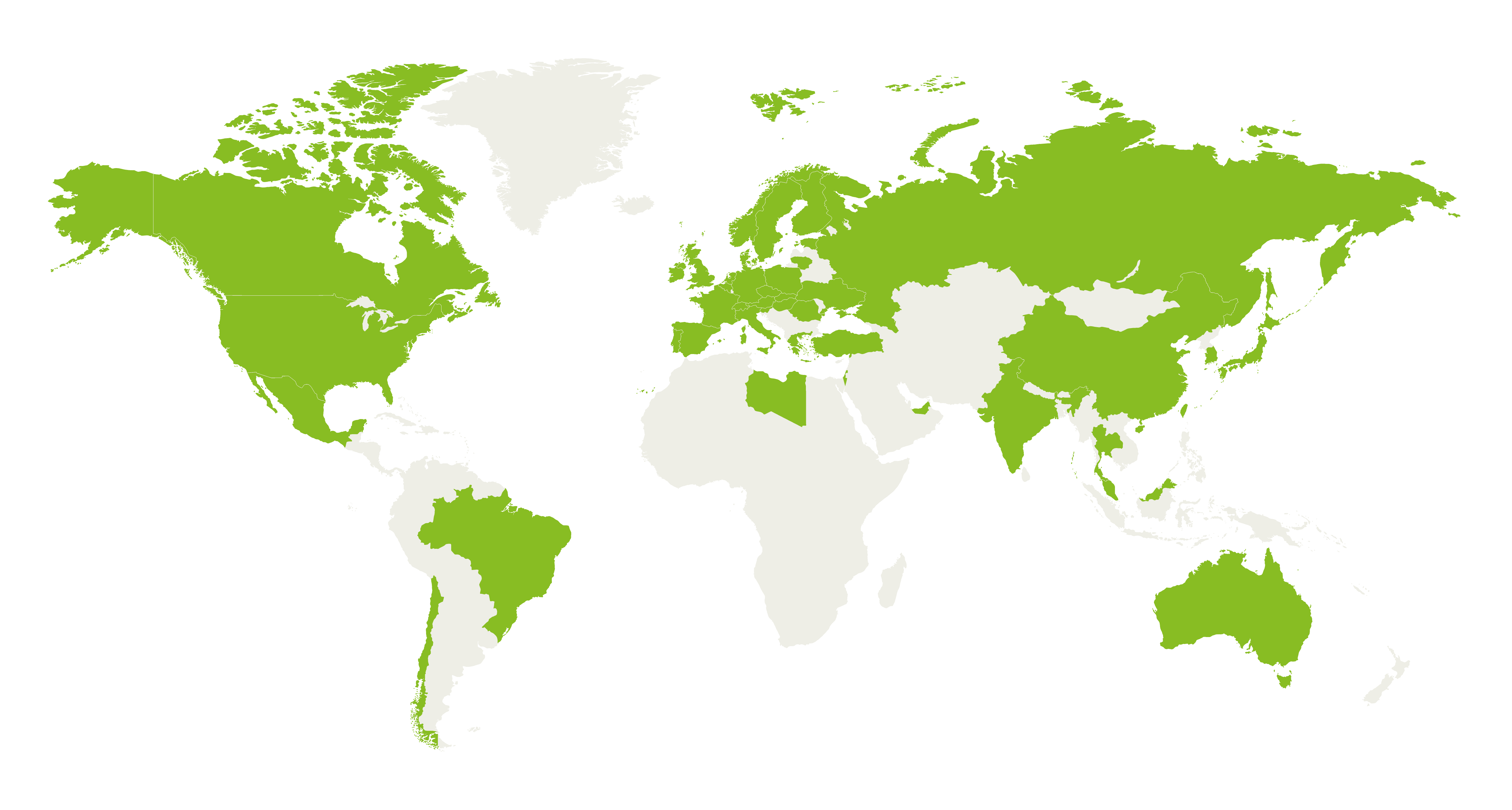

The machines, including all components, are manufactured here with the usual precision and with the highest quality standards. Our customers come from all over the world, as you can see on this map, which shows in which countries you can find Duespohl machines.

Being one of the most innovative players in its sector, Duespohl is an active member of technology networks and has executed several cooperation projects with scientific partners, especially in the context of the development of the RoboWrap

In the past, Duespohl has not only concluded some projects that have helped to take profile wrapping to the next level. Duespohl has also won prices, among them the LIGNA innovation price 2013. And we do not stop here. We keep on extending and intensifying our research and development activities to make sure our customers will always benefit from the latest technological possibilities.

Currently, the Fraunhofer Institute for Mechatronic Systems Design (Fraunhofer IEM) and Duespohl are working on a project to integrate artificial intelligence into the teaching process in profile wrapping. This project is part of the AI Marketplace, a new digital platform, supported by the Federal Ministry for Economic Affairs and Energy.

Duespohl as your partner

Cooperating with our customers means elaborating the ideal solution with you and for you, depending on the individual project’s demands.

For us, it goes without saying that we configurate a customised line according to your needs. Our Sales Engineers offer competent advice and help you to find the ideal combination of the large, smart and proven Duespohl components.

Each profile wrapping line of any series benefits from several intelligent solutions that help you to reduce set-up times and boost your productivity.

Just to give you one example: the grid system for the positioning of transport wheels and the quick-change system of the pressure rollers are part of our standard equipment of every line.

Price

-

Competent advice by our experienced sales engineers

-

Every line is tailored to your individual application

-

Qualified service technicians expertly install your line and provide on-site training

-

Lines designed for high production volume

-

Remote support for fast assistance

-

Low maintenance requirements