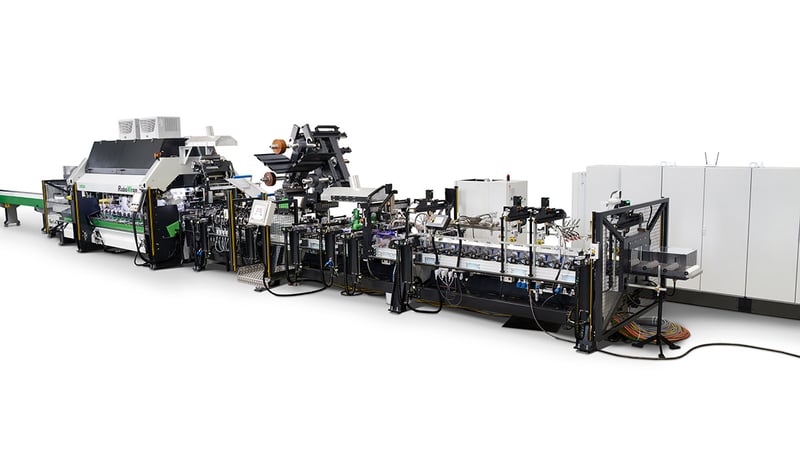

Foil-Heating-System FHS

Using this unit, you increase the process safety and surface quality of the wrapped profiles.

Ideal for

- all profile wrapping lines

- all laminating lines

Would you like to receive a free consultation to find out if the foil heating system is the solution you need?

Contact us for a non-binding, first conversation.

Description

In connection with powerful IR heaters that warm up the work pieces, the optimal temperature of the wrapping material is an indispensable requirement for comparable and improved adhesion. At the same time, it significantly reduces the amount of glue applied which helps you to save up to 30% or more on adhesive costs.

An important side effect is the improved surface quality of the wrapped profile which results from the thinner layer of glue applied and the improved flow, especially when it comes to highly viscous adhesives with contact to pre-heated surfaces.

Highlights

-

Constant foil temperature control, even for rapidly changing feed speeds thanks to automatic variation of the heating area

-

Independent from temperature of wrapping material before preheating

-

Independent from foil colour and structure

-

Anti-adherent coated surface

-

Low energy requirement, even at high feed speeds

-

Contactless foil temperature sensor, right in front of the adhesive application unit

-

No deformation of thermal foil during machine stops

-

No radiated heat/dazzling in surroundings

-

Transmission temperature can be selected dependently from the material

-

Not sensitive to vibrations/jolts

-

Simple handling and operating

-

Can be retrofitted to all existing machines with slot coater application system by Duespohl

Downloads