UniMelt

Ideal for

- EVA

- PUR

Would you like to receive a free consultation to find out if UniMelt is the solution you need?

Contact us for a non-binding, first conversation.

Description

UniMelt has been constructed to be energy efficient and with low maintenance requirements while contributing reliably to an undisturbed process and best wrapping results. Its mode of operation makes sure that the available hot melt glue has been freshly melted. Even longer interruptions of production, for example at the weekend, do not require specific measures thanks to the integrated air-drying system. It also has been designed to avoid burnings in the hot melt glue.

UniMelt prepares the glue according to the process's requirements while the maximum melting capacity ( up to 40, 80 or 160 kg) always depends on the specific type of adhesive. Refilling does not require an interruption of the production process.

Maintenance efforts are extremely low. Thanks to high quality non-stick coating and since all relevant parts are easily accessible, the necessary measures are easy.

The standard equipment includes:

-

Integrated dry air generation with a pressure dew point of -70°C, maintenance free

The optional equipment includes:

-

Integrated slot coater control

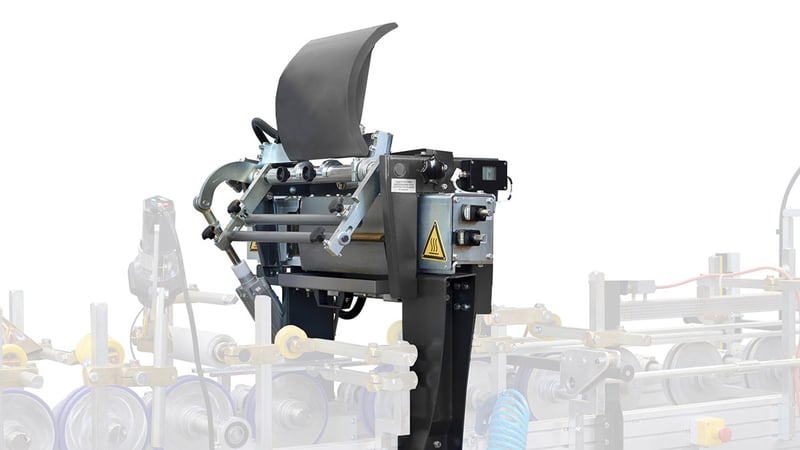

UniMelt 40

also available as a retrofit component, preferably in combination with a new SlotCoater

UniMelt 80

Example of retrofit premelter, including control cabinet

UniMelt 160

Full power: melting volume of up to 160 kg/h

Highlights

-

Thanks to special geometry and anti-stick-coating, adhesive residues can be removed easily

-

100% adhesive utilisation

-

UniMelt provides continuous melting, even during refilling

-

Language independent touch screen operating unit

-

Melting according to the process's needs

-

Careful melting process thanks to exact temperature control

Downloads